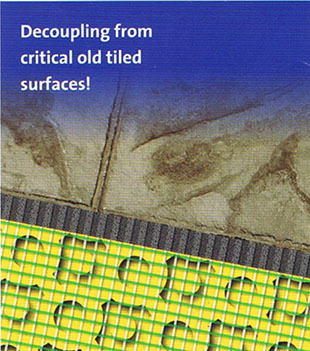

Crack SuppressionDecoupling, Crack Isolation, Cleavage Membrane, Suppression Membrane, Anti-Fracture System

CLICK HERE TO VIEW OUR RANGE OF MATTING

Is crack suppression membrane required on load bearing or traffic surfaces in the construction of a building?

Answer: If you do not care about cracked tiles or gaps appearing in your tracking surface then the short answer is NO!

However, if you want to eliminate costly future maintenance then crack suppression or anti fracture systems are an absolute necessity.

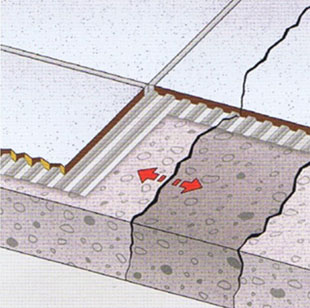

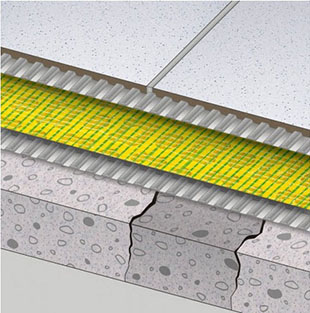

Cracks naturally occur in almost all surfaces due to seismic movement and /or climatic variations. In particular, concrete flooring substrates tend to shrink as the water in the concrete gradually evaporates. These shrinkage cracks can occur randomly throughout the substrate (floor) and/or wall. Potential problems emerge when a ridgid surface such as slabs, pavers or tiles are bonded to the concrete and the cracks in the concrete then migrate from the substrate out through the ridgid surface cladding. When this happens, the installed surface product (tile, slab, paver, etc) can be damaged, resulting in expensive repairs and or replacement.

The solution is to isolate the substrate from the applied surface material. This prevents the shrinkage cracks from transferring outward to the surface layer. Some designers, specifiers and/or architects seem to think that expansion joints are the answer to crack prevention yet this is far from the truth. Expansion joints are specific for calculated potential stress relief points in the substrate or foundation or slab. Expansion joints to not accommodate for random surface cracks or shrinkage between the major expansion points.

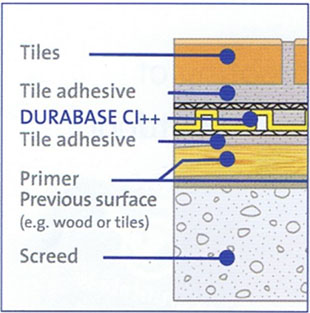

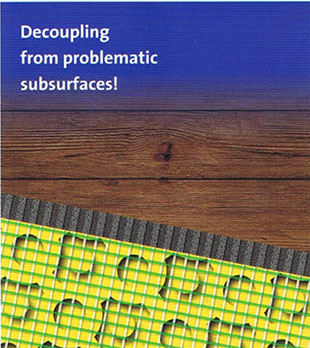

Also known as cleavage membranes or substrate membranes, the use is not simply limited to shrinkage but is equally important when covering or cladding surfaces made of different compositions or materials. One example could be using a bridging membranes to decouple the joint where concrete meets timber. There are obviously may variations of surface material compositions and in all cases, the most sensible alternative and also inevitably the only solution is to use a de-coupling system if you want to cover or coat the existing surface with a new surface.

Isolation Membranes are not just for crack supression, they can be used as water barriers, water proofing and efflorescence barriers ... More about decoupling and moisture membranes

Bridging The Gap.

|

CRACK SUPPRESSION = MAINTENANCE PREVENTION De-Coupling is quite often a more economical solution for the proper preparation of surface cladding as opposed to complete removal of existing surface to original substrate. Economics and time dictate that crack prevention in the first instance is the most sensible option. |

|---|