Expansion joint profiles for retail outlets or warehouses Series SB (for floors)

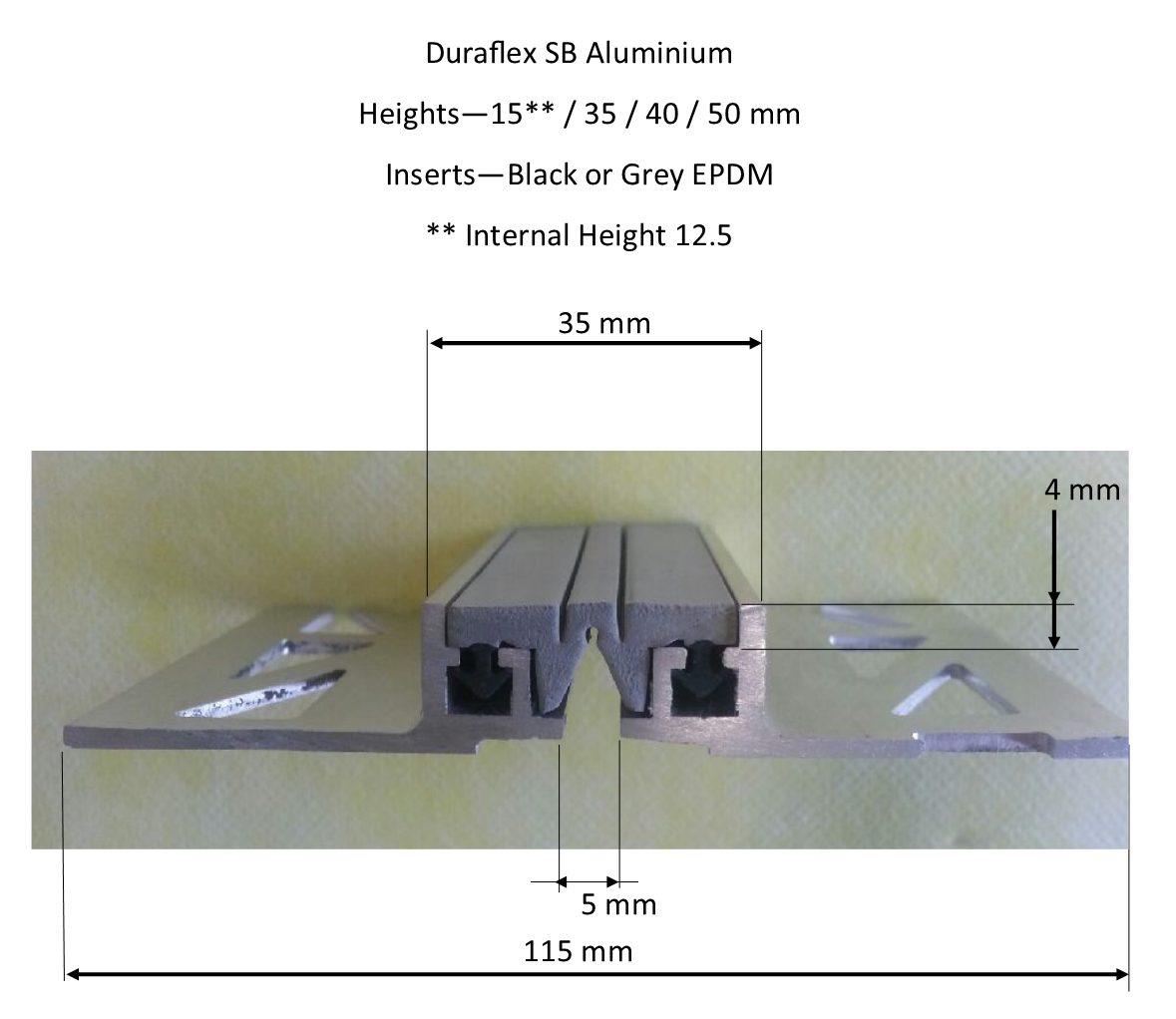

DURAFLEX SB Aluminium

Dural’s flexible DURAFLEX expansion joint profiles are manufactured for use in busy locations. They are highly resistant to wear and can be easily employed in retail outlets, warehouses or factories. The visible surface of the profile is 37 mm in the standard version and 45 mm in the reinforced version. Loads acting at a point are evenly distributed through the covering and the bedding via the inlay.

The profiles are available from stock for heights up to 90 mm. Greater heights are available on request. The aluminium profiles at the sides are bonded to a thermoplastic elastomer (EPDM) rail that is easily replaced. The specially developed inlay absorbs shocks and reduces the sound of footfall.

DURAFLEX aluminium profiles can also be used for walls and ceilings.

MATERIAL:

Flexible DURAFLEX expansion joint profiles consist of an aluminium girder section with a thermoplastic elastomer (EPDM) inlay. They are available in black or grey.

PROPERTIES:

Flexible DURAFLEX aluminium expansion-joint profiles may be used in all sorts of locations where no unusual chemical reactions are to be expected. In order, to avoid corrosion, cement should be handled with care. Since aluminium is susceptible to alkaline materials, mortar residues, tile adhesive or grout should be wiped immediately from all visible surfaces. The profile needs to be fully embedded in the contact layer. This avoids the creation of cavities where alkaline water might collect.

The thermoplastic elastomer inlay is resistant to weather and signs of age. The inlay is not subject to cracking as a result of UV light or ozone. The material can withstand a temperature range of –60° to +100°C. The inlay can be extended (by welding) to any length.

The use of these materials should nevertheless be carefully scrutinised with respect to their mechanical and chemical resistance in each individual instance.

INSTALLATION:

- DURAFLEX flexible expansion joint profiles should be selected according to the tile thickness.

- Tile adhesive should be applied to the edges with a toothed trowel.

- Press the DURAFLEX profiles into the adhesive bedding and align them. Expansion joints should be fully surrounded by the bedding.

- Securing brackets should be completely covered over with adhesive.

- Firmly press in the tiles and align them so that they are flush with the upper edge of the profile. Lay tiles so that they are fully tessellated.

- Allow a 2-mm gap around the profile.

- Completely fill the gap between tiles and profile with grout.

MAINTENANCE:

DURAFLEX profiles do not require any special maintenance. They are resistant to fungus and bacteria. They may be cleaned using ordinary cleaning materials. Cleaning materials may not contain hydrochloric or hydrofluoric acid and may not cause abrasion. The flexible joint can easily be replaced in the event of damage.